Blog

The future of seafood packaging starts here!

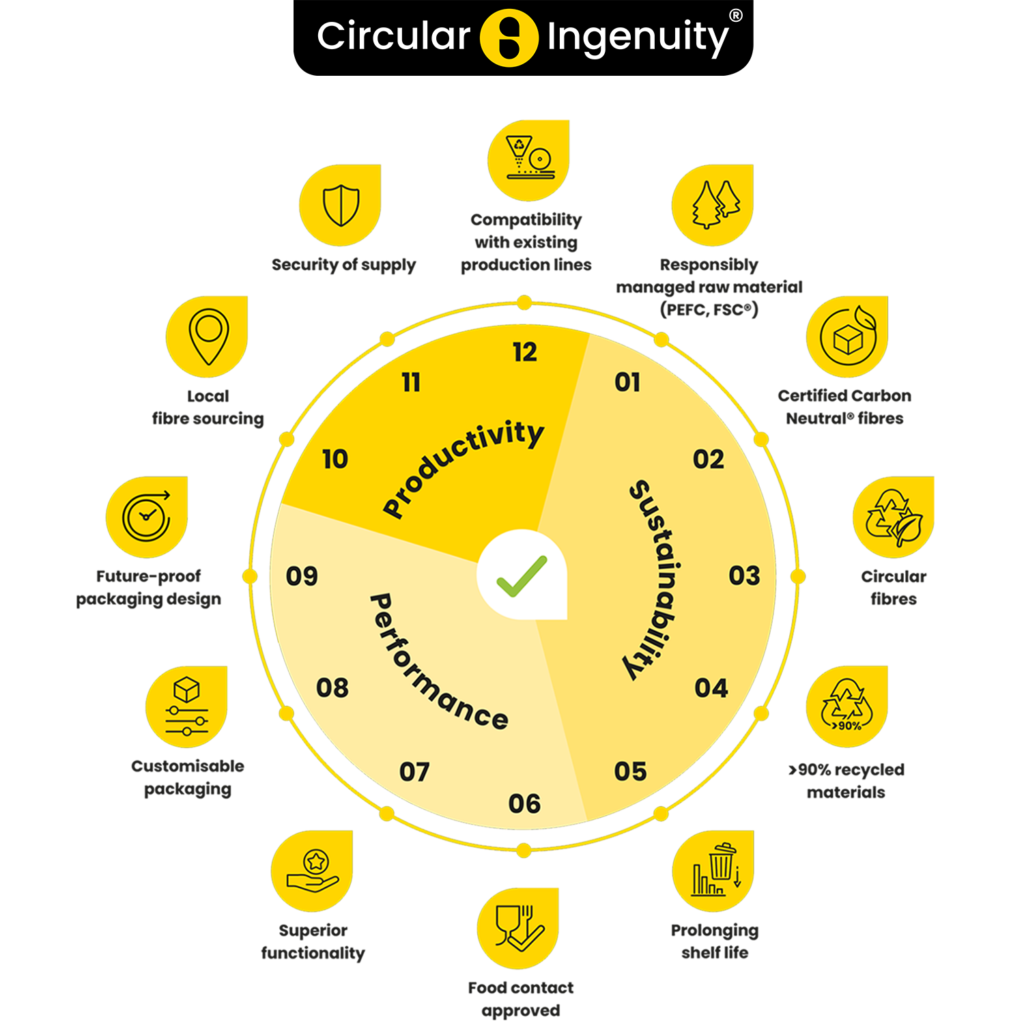

Solidus Circular Ingenuity is defining the next era of seafood packaging

The seafood industry faces a major challenge

How do we move away from expanded polystyrene ‘EPS’ fish boxes while ensuring food safety, efficiency, and cost-effectiveness?

With increasing regulations like the EU’s Packaging and Packaging Waste Regulation ‘PPWR’ and growing consumer demand for sustainability and packaging circularity, it’s time to rethink seafood packaging choices.

For decades, EPS has been the preferred packaging for seafood due to its lightweight structure, excellent insulation, and cost-effectiveness. However, from a sustainability standpoint, it poses significant challenges. Only 25% is recycled, while 30% is incinerated and the rest landfilled.*

Recycling solid board is less complex, less energy intensive and more cost effective than recycling EPS. This helps brands meet evolving consumer and regulatory expectations.

Reducing seafood waste with intelligent packaging

With mounting regulatory pressure, including the EU’s PPWR, the seafood industry is actively transitioning toward high-performance, sustainable packaging solutions that align with circular economy principles.

France has already set a precedent by committing to ban EPS seafood packaging by 2030**, and other European countries will follow suit in favor of more sustainable materials. This shift is not just inevitable, it presents a strategic opportunity for seafood companies.

“Rather than viewing regulations as obstacles, the seafood industry must embrace them as a driving force for innovation. Those who lead this transformation today will not only future-proof their businesses but also define the new standards of sustainable seafood packaging for the next decade.”

“One of the most common concerns we hear is whether alternative packaging can maintain seafood’s freshness.”

Traditionally, EPS has been favored for its insulation properties, helping to preserve quality and reduce seafood waste. Fibre-based solid board packaging has evolved significantly and is a strong alternative for EPS and plastic packaging.

The Solidus Techno Centre has partnered with leading seafood suppliers seeking to transition from EPS to future-proof packaging solutions. A prime example is French seafood company Réseau Le Saint, which approached Solidus with the goal of replacing EPS with fibre-based packaging supporting the transport from the harbour to the hospitality sector, not just for sustainability, but also for enhanced production efficiency, logistical optimisation, and brand differentiation.

At Solidus, we recognise that packaging goes beyond protection, it is a key driver of food quality, waste reduction, and sustainability.

That’s why we are making seafood packaging more intelligent with real-time monitoring of food quality. This ensures seafood reaches consumers in optimal condition, extending shelf life, minimising waste, and enhancing supply chain efficiency.

More than only just preserving freshness, our packaging solutions actively contribute to the EU Farm to Fork targets, supporting the transition to a fair, sustainable, and resource-efficient food system by 2030.

At the core of this transformation is our commitment to circular economy principles, ensuring that packaging is not only functional and efficient but can also be recycled at scale at end-of-life, a clear benefit versus EPS seafood packaging.

Packaging as a strategic advantage

For years, Solidus has led in fibre-based packaging, blending sustainability and performance through innovative solid board design, delivering strength, versatility, and circularity in one solution.

Firstly, the board is fully recyclable and designed for circularity.

Made from renewable certified PEFC or FSC® fibres, solid board seamlessly integrates into existing paper waste streams, ensuring easy and sustainable disposal and recycling. To guarantee this, we rigorously test the final packaging for recyclability, ensuring compliance with PPWR regulations and the ability to be recycled at scale at the end of its lifecycle. Currently, over 80% of paper-based packaging in Europe is recycled, setting a strong precedent for circularity.

Secondly, it’s strong and water-resistant.

With advanced innovative coatings, solid board can withstand moisture and cold storage, ensuring seafood remains fresh and protected.

Another key advantage is its significantly lower carbon footprint.

At our Coevorden mill, we have replaced fossil fuels with waste wood biomass, drastically reducing emissions to offer a Certified CarbonNeutral® board. This transition not only minimizes our own environmental impact but also helps support our customers, brands, and retailers in achieving their Scope 3 emission reduction targets, aligned with their climate commitments.

Additionally, logistics become far more efficient.

Solidus fish boxes take significantly less space than EPS when transported flat, meaning fewer trucks, lower logistic emissions, and reduced costs. This advantage considerably enhances supply chain efficiency, especially for brands exporting seafood globally.

At the same time, food safety remains a top priority.

FSSC 22000 and BRC-certified mills and converting plants ensure that seafood is packaged hygienically and meets strict industry standards.

Beyond sustainability, fibre-based packaging is a strategic advantage, reducing plastic waste to meet consumer expectations, optimizing logistics to cut costs, and integrating real-time freshness monitoring to enhance food safety.

For seafood brands, the shift to circular, efficient, and intelligent packaging isn’t just about compliance, it’s about staying ahead of competition.

The question is no longer if we move beyond EPS, but how fast we can drive this transformation to be PPWR compliant.

Solidus Circular Ingenuity is leading the way, ensuring future-proof seafood packaging.

Discover more, please contact Jesse Rep – Head of Sustainability: info@solidus.com

* European Commission LIFE EPS SURE on LIFE Public Database

** EUMEPS Update on French Styrenic Packaging Regulations: Extension to 2030 and Legislative Developments