Blog

Shelf life extension for fresh fruit and vegetables: reducing food waste with circular fruit packaging

Extending freshness, reducing waste

The fresh produce industry is under increasing pressure to reduce food waste, achieve sustainability targets and respond to changing consumer demands.

Fruit and vegetables account for the largest proportion of global food waste, making them a critical focus area for improvement. At the same time, retailers and producers are seeking packaging solutions that are both environmentally responsible and commercially viable. By extending shelf life and preserving freshness, the right packaging can help reduce waste across the supply chain while supporting a more circular approach to fruit packaging and vegetable packaging.

Solidus is collaborating with innovation partners, including Fresh Inset, to develop smart packaging solutions that can extend the shelf life of soft fruit by delaying the natural ripening process. By integrating Fresh Inset’s Vidre+™, a sticker that slowly releases a freshness protectant called 1-MCP, into our fibre-based packaging, we can preserve the quality and appearance of soft fruit for longer without the need for additional processing or infrastructure. Initial trials with soft fruit show promising results. Interested growers are invited to participate in future trials.

Food waste within the fruit and vegetable industry

Globally, around one-third of all food produced is lost or wasted each year, contributing roughly 10% of greenhouse gas emissions. Fresh fruit and vegetables account for a significant proportion of this waste, with nearly 45% going unsold, spoiled, or discarded. From growers who lose valuable harvests, to retailers struggling to maintain shelf quality, to consumers discarding food at home, every link in the chain bears the cost. One of the most effective ways of addressing this challenge is to extend the shelf life of produce, ensuring it stays fresh for longer as it moves from field to fork.

Shelf life plays a crucial role. Every additional day of freshness can reduce waste, improve profitability, and enhance consumer satisfaction. Fruit packaging that effectively controls moisture, temperature, and ethylene exposure directly influences ripening and spoilage, making it a strategic tool for the industry.

Circular fibre-based fruit packaging as a solution

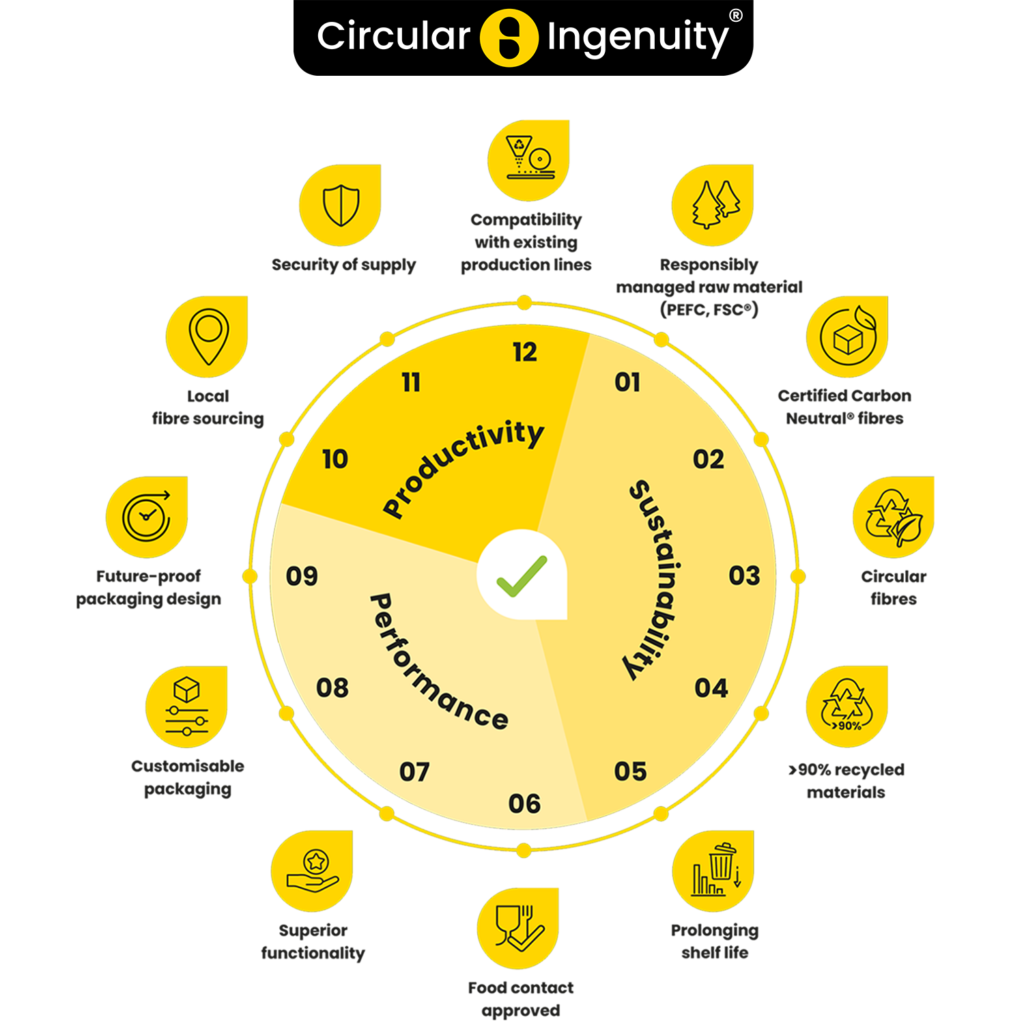

Circular fibre-based packaging offers a response to these challenges. By combining sustainable materials with designs that protect produce and maintain freshness for longer, food waste can be reduced while contributing to a more sustainable supply chain.

Growing consumer demand for environmentally responsible packaging, alongside increasing regulations such as the EU Packaging and Packaging Waste Regulation (PPWR), makes it essential for producers to reconsider their packaging choices. Recyclable solid board made from recovered fibres minimizes environmental impact and meets consumer expectations.

Unlike most plastic packaging, circular fibre-based solutions are designed to be recycled after use. Fibre-based board can be processed multiple times, reducing waste while providing robust protection during transport and storage. It protects fruits and vegetables from damage and spoilage, helping to extend shelf life and maintain quality from farm to retailer to consumer.

At Solidus, our packaging solutions are specifically designed to meet the needs of the fresh fruit and vegetable industry. Our water-resistant, high-strength solid board packaging protects produce from moisture and handling, helping to extend its shelf life and maintain its quality.

Solidus’ solid board packaging is produced using FSC®- or PEFC-certified fibres, is fully recyclable and can be seamlessly integrated into existing paper recycling streams. It meets upcoming PPWR requirements while providing essential protection for moisture-sensitive produce.

Fruit packaging and sustainability with measurable impact

At Solidus, sustainability means actively reducing our carbon footprint. At our Coevorden mill, for example, we have replaced fossil fuels with waste wood biomass, enabling us to offer Certified CarbonNeutral® board. This reduces our operational emissions and helps growers, exporters and retailers to lower their Scope 3 emissions, to which traditional packaging solutions can contribute up to 20%.

In addition to being made from CarbonNeutral® board, our flatpacked solid board packaging optimises storage and transport, reducing emissions and lowering the number of truck movements and associated costs. Life cycle assessments of the Solidus punnets and MAP trays show a 30% reduction in the carbon footprint compared to traditional plastic packaging. Together with the use of renewable resources, this further supports the environmental benefits of circular fibre solutions.

Why it matters?

- Support significant reduction of Scope 3 emissions

- Packaging made from renewable resources

- Optimise logistics efficiency with flat-packed, space-saving solutions

- Show environmental leadership to strengthen your brand

From compliance to competitive advantage

Fibre-based solutions extend freshness, reduce plastic waste, optimise logistics and provide tangible sustainability credentials. Companies that adopt circular fruit packaging or vegetable packaging early on can reduce waste, improve profitability, and establish themselves as leaders in a market that increasingly values sustainability. The real challenge lies in how quickly the industry can accelerate this shift, and which company will set the benchmark for circular packaging in fresh produce.

With every step towards circular packaging, the industry takes a step closer to reducing food waste and achieving measurable sustainability impact.

Discover more about our fruit packaging or vegetable packaging solutions, please contact us info@solidus.com